Thermal, physical and mechanical characterization of volcanic tuff masonries for the restoration of historic buildings

M. M. Barbero-Barreraa*, N. Flores-Medinaa,b,c, E. Moreno-Fernándeza

a. Department of Construction and Technology in Architecture. Escuela Técnica Superior de Arquitectura, Technical University of Madrid, (Madrid, Spain)

b. Universidad Europea de Canarias. School of Architecture. Department of Projects and Representation of Architecture. (La Orotava. Spain)

c. Departamento de Construcción Arquitectónica, Escuela de Arquitectura, Universidad de Las Palmas de Gran Canaria, Campus Universitario de Tafira, ( Las Palmas de Gran Canaria, Spain).

*mar.barbero@upm.es

| |

ABSTRACT

An in-depth knowledge of building materials is essential in order to preserve them. Tuffs are one of the main types volcanic rocks in the Canary Islands. They are mainly used in masonry or as a filler of the ornamental parts of the façades. In both cases, they have been protected to guarantee their durability. However, in recent years, the renderings have been eliminated and the stone has been exposed to the elements. In this paper, two types of Canary-Island volcanic tuffs were characterized from a physical and mechanical point of view as well as their energy conservation, in order to better understand their behaviour and analyze the criteria for preserving them. Thermal conductivity and fluxes increase 2-3 times in wet conditions, as compared to dry ones. This, together with their high porosity demands the use of renderings to avoid stone decay, and at the same time improving living conditions.

|

| |

RESUMEN

Caracterización térmica, física y mecánica de las fábricas de toba volcánica para la restauración de edificios históricos. El conocimiento de los materiales de construcción es esencial para garantizar la conservación de las construcciones. Las tobas son uno de los principales tipos de rocas volcánicas de edificios tradicionales y monumentales en Canarias. Éstas se usaban tanto fábricas como en ornamentos pero, en ambos casos, se protegían para garantizar su durabilidad. En los últimos años, los revestimientos están siendo eliminados exponiendo la fábrica a los agentes atmosféricos. En este artículo, dos tipos de tobas volcánicas de Canarias son caracterizadas desde el punto de vista físico, mecánico y energético para analizar qué criterios son los más adecuados para su conservación. La conductividad térmica y el flujo térmico aumentan entre 2-3 veces en muestras húmedas en comparación con las secas. Esta circunstancia junto con la elevada porosidad exige el uso de revestimientos para evitar la degradación de las piedras, al tiempo que mejoran las condiciones de habitabilidad de los espacios interiores.

|

1. INTRODUCTIONTOP

It is essential to preserve our cultural heritage not only the identity of the cities and villages but also the general welfare and quality of life as an instrument of social cohesion (1). It is especially clear in the case of historic architecture: palaces, castles or cathedrals, among others. However, in the case of vernacular architecture there is still a lack of recognition of its value and it is sometimes focused on the romantic view of this type of heritage. Consequently, in 2014 the national plan for traditional architecture was approved in which the theoretical bases related to the general ideas about the traditional architecture was established, as was the criteria to register and research this type of heritage (2). Hence, based on the importance of preserving this type of architecture, a more profound knowledge of the properties of the traditional materials is required. It is essential to decide the compatible intervention as well as selecting the most appropriate techniques to restore them. Furthermore, the ongoing increase in energy consumption demands an precise knowledge of the energy performance of the buildings as well as their constructive systems in order to select the most suitable intervention (3).

Natural stone is one of the most noble construction materials since it is a symbol of durability related to our historical heritage. For this reason, volcanic stones have traditionally been used in those areas in which they could be found them. All of them are, nowadays, exposed to a gradual and widespread decay due to the trend to eliminate the renderings and plasters that protect them. This new ‘fashion’ not only worsens the durability of the structures but also the thermal performance of the buildings as researched by Luxán et al (4). Hence, an urgent analysis is required to characterize these materials in order to propose recommendations to sustain a long-term performance (5).

In Spain, there are several areas of volcanic origin: Campo de Calatrava in Ciudad Real province, Olot in Gerona, Picasent in Valencia, an area between Murcia and Almeria and the Canary Islands (6). As regards the latter, basalts, phonolites and tuffs are the main types of volcanic rocks used in traditional building in the Canary Islands (6, 8). The stonework made of basalts and phonolites is mainly used in exposed facades and ornamental elements; tuff is mainly used in masonry or as a filler of the ornamental parts of the façades.

Tuffs are volcanoclastic rocks, formed by a volcanic conglomerate (matrix) in which the grains are of volcanic origin. The consolidation of tuff may occur through compaction (load) or cementation (chemical changes in the matrix) or even welding (load and temperature) (9,10). Tuffs have been studied from both a geological point of view and as architectural heritage conservation in Mexico (11, 12, 13), Italy (14, 15), Turkey (16, 17) and Korea (18) among others. Their chemistry (13–17, 19–21), and mineralogical characterization (16, 17) were considered to set the mechanical properties of masonry (9, 15, 20), mechanical and physical (16, 17) and their durability (16, 17, 18, 21). However, there are no research works into the specific type of volcanic stones in the Canary Islands; neither from the mechanical and physical point of view nor from their thermal performance. In fact, as regards the latter, there are no studies, as far as we know, in which the thermal performance of the tuffs are considered.

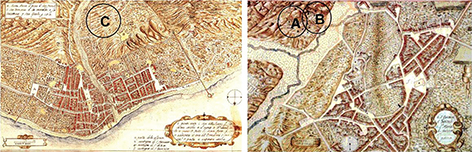

Because of the numerous types of stone on the Canary Islands, the research centres on the island of Gran Canaria. It is the second most populous island in the archipelago and the third largest after Tenerife and Fuerteventura. The selection is based on the greater implications in the restoration and renovation of the buildings. Selected tuffs were used in traditional building from two historical cities: Telde and Las Palmas de Gran Canaria (Figure 1). Hence, the research centres in those areas due to their cultural significance. In historic buildings, tuffs were used as the main building material for load-bearing masonry because of their availability.

|

Figure 1. Maps by the engineer Leonardo Torriani. In 1590, on the left the map of Vegueta-Triana (Las Palmas de Gran Canaria, Gran Canaria) and, on the right, San Francisco and San Juan in the 16th Century (Telde, Gran Canaria). On both maps the quarries of tuff near the historical sites are shown: Batán-Barranco Seco (B) and Caserones (C). On the Map of Caserones the pre-hispanical site of Tara in Telde can be also seen (A). Figure 1. Maps by the engineer Leonardo Torriani. In 1590, on the left the map of Vegueta-Triana (Las Palmas de Gran Canaria, Gran Canaria) and, on the right, San Francisco and San Juan in the 16th Century (Telde, Gran Canaria). On both maps the quarries of tuff near the historical sites are shown: Batán-Barranco Seco (B) and Caserones (C). On the Map of Caserones the pre-hispanical site of Tara in Telde can be also seen (A).

|

|

The area of San Francisco, in Telde, was subject to research as it was the first Spanish Government in the Canary Islands, dating back to the 14th Century (22). In the Las Palmas de Gran Canaria, Vegueta and Triana areas, dating from the 15th Century with colonial architecture from

16th to 18th centuries, they were classified by the UNESCO as World Cultural Heritage (22–25). Geological maps of both regions are available at IGME website (26).

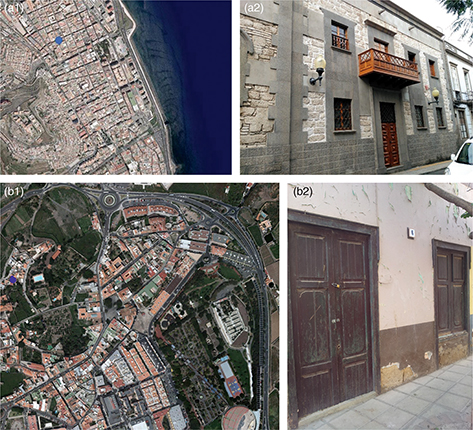

From an energy point of view, buildings can be considered as an environmental resource as well as their renovation as the best proposal for reducing the consumption of energy (27, 28). The importance of enhancing energy efficiency strategies is highlighted by the increase in investments in this sector in such a way that., in the IEA countries., in 2014, $550 billion were quantified compared to about $200 billion, in 2004 (29). However, the lack of accurate knowledge on the performance of the materials performance gave rise to an accelerated decay of the stones due to the elimination of the protective rendering (Figure 2).

|

Figure 2. Historic building with unprotected wall surface of tuff stone. Figure 2. Historic building with unprotected wall surface of tuff stone.

|

|

The mechanical, physical and thermal characterization of two types of volcanic tuffs in wet and dry conditions is evaluated in this paper. The in situ U-values of two buildings were also compared to simulate the pseudo-steady state conditions to better understand their behaviour and to analyze the criteria for preserving them in restoration works. Furthermore, the methodology and the results can be extended to the restoration of other types of similar tuffs used in buildings of national heritage throughout the world such as Mexico, Turkey and Italy among others.

2. MATERIALS AND METHODSTOP

2.1. MaterialsTOP

Two types of volcanic tuffs which are found throughout the Island were selected: a white-dark located in Vegueta-Triana (Las Palmas de Gran Canaria) and a brown-coloured from San Francisco (Telde). Both of them were collected from different areas from several demolition sites in order to obtain a representative sample of each type of stone. Additionally, care was taken in their collection and selection in such a way that their physical integrity was maintained. Figure 3a and Figure 3b show their external appearance.

A Bruker D8 Advance diffractometer with Bragg geometry was used. The minerals were analyzed using the DIFRRACplus program and a Rietveld semiquantitive analysis with TOPAS software. As can be seen in Table 1, great differences in mineralogical composition were observed although albite, sanidite and chabazite were the main components of both types of stone.

Table 1. XRD semi-quantitative phase analysis of the two tuff stones.

| Sample |

Albite (%) |

Sanidine (%) |

Kaolinite (%) |

Tremolite (%) |

Chabazite (%) |

Hematite (%) |

Quartz (%) |

Diopside (%) |

| White-dark tuff |

18 |

16 |

7 |

15 |

34 |

6 |

- |

5 |

| Brown tuff |

16 |

15 |

6 |

13 |

41 |

1 |

3 |

5 |

Moreover, a chemical analysis in accordance with the UNE-EN 197:2000 European Standard had been carried out on a non-weathered sample of each tuff (Table 2). We can see a higher amount of silica and alumina in the white-dark tuff and a higher content of calcite in the brown tuff.

Table 2. Chemical analysis of the two types of stone.

| Sample |

SiO2 (%) |

Al2O3 (%) |

Fe2O3 (%) |

CaO (%) |

MgO (%) |

Na2O (%) |

K2O (%) |

MnO (%) |

TiO2 (%) |

P2O5 (%) |

| White-dark tuff |

59.06 |

19.52 |

3.70 |

0.28 |

0.19 |

3.05 |

5.21 |

0.23 |

0.69 |

7.85 |

| Brown tuff |

40.51 |

10.93 |

3.60 |

11.74 |

12.08 |

4.55 |

1.33 |

0.18 |

3.96 |

1.15 |

Given their heterogeneity, six samples were prepared for each test. For preparation, they were firstly reduced in size by hand followed by an adjustment using a wet-cut circular saw to achieve the dimensions of the samples. Afterwards, the samples were dried in a chamber at 40 ±5°C for two weeks until a constant weight was reached. The dry materials were then introduced into sealed polyethylene bags until testing.

2.2. Mechanical PropertiesTOP

Compression and flexural tests were carried out. For compression tests, samples of 100 mm × 100 mm × 100 mm dimension were prepared. 400 mm × 150 mm × 150 mm were used in the flexural tests. Both were carried out following the EN 1926:2006 (30) and EN 12372:2006 (31), European standards respectively.

Samples of 200 mm × 200 mm × 25 mm were cut for abrasion resistance tests. The importance of this test is based on its use in bases and pavements. It followed the EN 14617-4:2005 (32) European standard. Finally, Shore A, C and D hardnesses were applied in the materials (33).

2.3. Physical PropertiesTOP

The importance of the hydric performance of samples is clear in terms of weathering. It is especially interesting in these stones given the high relative humidity in the Islands as well as the aforementioned trend of eliminating renderings. In this case, the water absorption coefficient under atmospheric pressure followed by a desorption test developed by LNEC (34), together with water absorption by capillarity were carried out under the EN 13755:2008 (35) and EN 1925:1999 (36) European standards respectively. Furthermore, the bulk density of samples was determined under the EN 1936:2007 (37) European standard method, as was the open porosity. To assess the microstructure and pore network of the samples thin laminas were developed and observed using a petrographic Kyowa Bio-Pol 2 with a plane-polarized light (//N) on a thin lamina, 30 µm thick, of the tuff stones and adhered to a glass slide with epoxy resin. The images were obtained with camera adapted to the microscope: the Moticam 2300 3.0 M-pixel. The thin lamina was obtained from the more significant parts of both tuff stones.

2.4. Thermal propertiesTOP

Thermal conductivity and specific heat tests were carried out. As the samples are commonly exposed to the outdoor surface, it was considered that thermal emissivity could be of great interest in estimating the radiative performance of the constructive systems.

Manufacturer and Navacerrada et al described the thermal conductivity apparatus and its operation (38,39). It is based on the measurement of temperatures of both sides of samples placed between the hot source at 60°C and the laboratory conditions when compared to a reference material of known thermal conductivity. To guarantee the accurate measurements, the thermal flow is determined under steady-state conditions, by means of the heat conduction in the sample as well as the air

- wall heat transfer (39). It commoly implies that measurements were taken at about 5–6 hours after the beginning. In this case, six samples of 200

mm × 200 mm × 25 mm were prepared for the thermal conductivity.

Given the importance of the water content in porous materials, a test with saturated samples was carried out. In this case, the samples were wrapped in polyethylene films to seal them. Given the evaporation of water during the test, the water content was determined by differences in weight when measurements were taken and after drying them in a chamber at 40±5°C up to a constant weight.

Specific heat was measured using a SDT Q600 unit Differential Scanning Calorimeter (TA Instruments). It followed the Instrument Technical steps for measuring the specific heat which consisted of a comparison among the baseline, DSC sample and DSC reference material. The latter was synthetic sapphire. The tests were ramped from 0°C to 130°C at 10°C/min, under a flow of N2 (100 cm3/min) based on preliminary tests. For this test, the samples were cut into pieces of about 6 mm and 1 mm in thickness, with a total weight of about 50–60 mg. To minimize errors due to the water content in the samples, before testing they were dried for 48 hours. Furthermore, two sample platinum pans were used to control the loss of weight.

The hemispherical thermal emissivity was determined using a RD1 portable emissometer with an AE1 detector in the range of

3,000–30,000 nm. The device is based on the sample being heated to 82°C and a control by a differential thermopile with low and high emissivity areas. It works in such a way that it creates a linear correlation between the sample radiation and two reference materials according to the ASTM C1371-04a (40) standard. In this case, specimens of 100x100x10 mm3 were used.

2.5. Simulation in a pseudo-time dependent stateTOP

Finally, the thermal performance of four types of constructive systems of façades was estimated by their simulation in a pseudotime-dependent state. It was carried out using Antesol V.6 software developed by Monroy (41). The constructive systems consisted of a masonry wall, 40 cm thick, with and without a lime rendering of 2 cm and a gypsum plaster of 2 cm to analyze the differences. The thermal resistance was estimated based on the result tests and the literature in the case of the renderings. Hence, the thermal resistance, in dry conditions, were 0.609 (m².K)/W and 0.633 (m².K)/W for white-dark tuff, and 0.654 (m².K)/W and 0.675 (m².K)/W for brown tuff with and without finishings, respectively. Given the importance of water content on the thermal resistance, a simulation with the stones in a wet state was carried out. In this case, the thermal resistance was 1.976 (m².K)/W and 1.764 (m².K)/W for the white-dark tuff and 1.376 (m².K)/W and 1.294 (m².K)/W for brown tuff with and without finishings, respectively.

In all cases, south orientation façades were stated. As it is supposed that the buildings were placed in an urban area, the albedo was fixed at 0.2. Furthermore, climatic data was provided by the Spanish Weather Forecast (42) for Gran Canarias and three types of climate were considerd at sea level (0–350 m), at 350–1000 m and over 1000 m according to the classification of the Spanish Thermal Code (43). The solar factor was assumed to be 0.8 on sunny days and 0.1 on cloudy days.

About the finishing properties, they were adjusted to the type of material. Roughness was 0.40 for both types of stones and

0.2 in for renderings and plasters. Outdoor absorptivity and emissivity was adjusted to the test values and the literature for the renders and plasters (0.90 of emissivity and 0.80 of reflectance). Indoor absorption was fixed at 0.3.

2.6. Monitoring under real conditionsTOP

Complementary to the previous analysis, two buildings were monitored (Figures 4a and 4b). The equipment was a TESTO model 435. The thermal transmitance is estimated as a comparison between thermal fluxes from the outside and inside temperatures (44), based on the ISO 9869:2014 standard.

|

Figure 4a. Placement of selected building with white-dark tuff in Las Palmas de Gran Canaria. Figure 4a. Placement of selected building with white-dark tuff in Las Palmas de Gran Canaria.

Figure 4b. Placement of the selected building with brown tuff in Telde.

|

|

The monitoring was carried out during a summer season, when the relative humidity was usually higher and its effect on the performance of the building could be analyzed. Sensors were placed on the south façade, due to the comfort conditions outside and the need to achieve at least 15°C of difference for accurate measurements (45, 46). The tests lasted 7 days or 168 hours, taking into account that the thickness was under 90 cm, following the recommendations of previous researches (47). Both of the selected areas were exposed under the same conditions to solar radiation and wind as well as the lack of heat sources at the inner surfaces, that could affect the comparison. At the same time, both the indoor and outdoor temperatures were recorded using TESTO loggers.

Finally, the aim of this part of the research was to analyze the influence of water content on the thermal transmittance. It was evaluated, in the same building with the same construction system and external conditions, with the difference between the thermal transmittance on the ground floor, close to the pavement (20 cm from the ground), and the first floor.

3. RESULTS AND DISCUSSIONTOP

3.1. Mechanical Properties TOP

Table 3 shows the results of the mechanical tests. The mechanical strength is less than other volcanic stones but is in accordance with that of some tuff stones (11, 13, 20). For instance Cappadocian tuff presented a mean value of 6.53 MPa and 2.16 MPa in dry and saturated conditions respectively

(16), showing a reduction in the compressive strength when saturated. However, tuff properties are very different depending on their welding conditions and conservation, for instance western Mexico tuff studied by Pérez et al. showed a compressive resistance of 19.7 MPa when it is not altered and 14.9 when has been submitted to weathering. In the same work, but in the case of a yellow tuff, the resistance was 41.6 MPa when the tuff is fresh and reducing its resistance to 8.9 MPa when altered.

Table 3. Mechanical properties of the tuff stones

| |

White-dark tuff |

Brown tuff |

| Compressive strength in dry conditions (MPa) |

5.54 |

6.75 |

| Compressive strength in saturated conditions (MPa) |

2.59 |

6.55 |

| Flexural strength (MPa) |

0.69 |

1.22 |

| Shore C Hardness (matrix) |

65 |

81 |

| Abrasion resistance (mm2) |

4.0 |

4.2 |

In this work, the compressive and tensile strength of the white-dark tuff was 22% and 76%, respectively, less than that of the brown tuff which is in relation to the physical properties in section 3.2. A significant variation in the properties has been found, especially in the white-dark tuff because of its porosity caused by the alteration of the matrix (16) in the presence of water. At the same time, the highest quartz content in the brown tuff justified its higher performance in terms of mechanical strength. It is in accordance with the statements of different authors (48). In addition, the variation was limited to 5% to get a representative value.

In addition, the average value of the flexural / compression strength ratio was 0.12 and 0.18 in the white-dark tuff and in the brown tuff, respectively. It implied that the elasticity modulus would probably be low (49), as it is common in traditional materials. Furthermore, it is in agreement with the strain for maximum strength. Tuff masonry showed a considerable plastic capacity as stated in the literature. Calderoni et al established the plastic capacity of the masonry of tuff stones, with a good transversal interlock, depending on the arrangement of the stones and the type of mortar

(15)

The compression strength and hardness are also related. White-dark tuff shows the lowest values from 40 to 65 in C scale depending on the alteration of the matrix. Areas without alteration in the matrix were selected for the abrasion resistance test. This explained the limited differences of 5% between both stones. From the results it can be determined that both of the tuffs can be permitted on low-moderate uses, in accordance with UNE-EN 14617-4 (32). It means that they can be used horizontally, vertically indoors as well as vertical outdoors under protection.

Complementary to this, mechanical tests were carried out on the saturated samples. As was expected, both of them considerably reduced the compressive strength by 53.2% in the case of the white-dark tuff and 3% in the brown. This result is considered of great importance in this type of material due to its porosity.

3.2. Physical PropertiesTOP

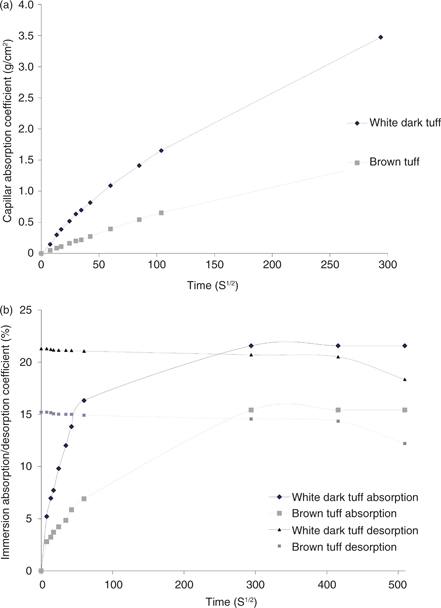

The white-dark tuff showed a 16% lower bulk density than the brown tuff (Table 4). On the other hand, the latter showed less open porosity than white-dark tuff. The water absorption coefficients by capillarity

(Figure 7 and Table 4) of white-dark tuff when compared to the brown one should be highlighted. It implies that the pore structure is different in both even though pores are smaller in the former.

Table 4. Physical properties of the tuff stones

| |

White-dark tuff |

Brown tuff |

| Bulk density (kg/m3) |

1,323 |

1,581 |

| Open porosity (%) |

36.06 |

22.64 |

| Water absorption at 24h (%) |

21.57 |

15.41 |

| Water absorption by capillarity at 24 h (g/cm2 s1/2) |

1,020.86 |

429.36 |

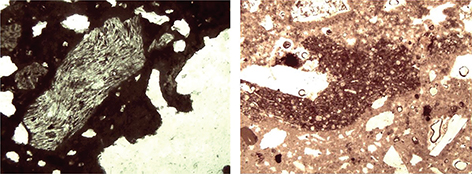

In Figure 5, the images obtained on a thin lamina with the petrographic microscope at 400x are presented, obtained under a plane-polarized light (parallel nicols //N).

|

Figure 5. The left-hand image is of a thin lamina obtained from the white-dark tuff and on the right, the brown tuff (//N 400X). The white areas indicate porosity. Figure 5. The left-hand image is of a thin lamina obtained from the white-dark tuff and on the right, the brown tuff (//N 400X). The white areas indicate porosity.

|

|

In Figure 5, we can observe the white-tuff //N at 400X, a salic trachytic phononolitic tuff with a vitreous matrix, with fragments of sanidine and a communicated porosity. The right-hand image shows the basalt-trachyte tendency of the brown-tuff. The brown tuff is a breccia tuff with a bigger welding rate of the matrix and a larger number of vitreous phases than the white tuff analyzed. Moreover, its porosity is less connected than that of the white-dark tuff, where areas without mass can be observed in the left-hand image.

Compared to other work found in the literature, porosity can vary from 38.29% in the Cappadocian samples (16) to 10.5% white-dark tuff and 27.4% yellow tuff from western Mexico (12). This performance is directly related to the higher examples of decay in the white-dark tuff compared to the brown, as well as the relationship between porosity and mechanical strength or hardness (50–52). It is of interest in these cases of external exposure to the elements which may easily cause damage and which reduces their strength drastically as previously mentioned, together with their durability (4), even more so by taking into account the salt crystallization probability due to the atmospheric conditions (53,54). In the Mexican case (12) the weathering suffered by tuff increased the porosity 3.1 times and 2.02 times in the cases of white and yellow tuff respectively. Weibern tuff (Germany) and Loseros tuff (Mexico) showed 37.1% and 7.06% respectively, in the study presented by Wedekind et al (55).

In Figures 6a and b, water absorption by capillarity of the tuff stones can be observed when exposed to capillarity water (Figure 6a) or immersed (Figure 6b). Differences between the brown and the white-dark are clear in terms of absorption; although they behaved in a similar way as regards the desorption process (Figure 6b). The latter requires almost two weeks to achieve a constant value compared to the 24 hours in the absorption process. This performance should be highlighted when water can rise through capillarity as highlighted by Veiga (34). The water absorption immersion is less than the Cappadocian tuff, which showed 38.29% by weight, although the time for absorption and desorption has not been obtained (16).

|

Figure 6. a) Relationship of the capillary absorption coefficient with the square of time in the two groups of tuff. b) Relationship of the absorption coefficient under an immersion and desorption coefficient with the square of time in the two groups of tuff. Figure 6. a) Relationship of the capillary absorption coefficient with the square of time in the two groups of tuff. b) Relationship of the absorption coefficient under an immersion and desorption coefficient with the square of time in the two groups of tuff.

|

|

Hence, once again, the physical properties of the stones reveal the need to reduce the rate of infiltration of water and pollutants as well as their movement through the stone to control the mechanical performance (48) and reduce their weathering (56). Indeed, the wetness effect due to the relative humidity as well as the rain noticeably gave rise to a reduction in strength

(15, 48) which is recovered when the stones dry. Because of this, extensive research has been carried out in recent decades to develop compatible treatments for stone-based protection (11, 12, 19).

3.3. Thermal propertiesTOP

In Table 5, a summary of the thermal properties of the analyzed stones is given. The results are of great interest since there is a lack of information regarding these properties in the literature, in spite of the fact that thermal conductivity is related to the bulk density and the porosity. However, a limited difference of 6% can be observed between both. It should be highlighted that both thermal conductivities are noticeably under the standard values considered for porous natural stones. A thermal conductivity of 0.55 W/(m².K) is given by the standard (57) which is in accordance with several research works which shown values from 0.52 to 1.79 W/(m.K) for higher bulk densities of about 2,000–2,100 kg/m3 (58–59). It showed that specific and detailed research should be carried out to characterize each building material clearly.

Table 5. Thermal properties of the tuff stones

| |

White-dark tuff |

Brown tuff |

| Thermal conductivity (W/(m².K)) |

0.253 |

0.270 |

| Specific heat capacity at 10–80°C (J/kg.K) |

1.165 |

1.305 |

| Hemispherical thermal emissivity (per one) |

0.94 |

0.92 |

In Las Palmas de Gran Canaria, the annual relative humidity is 68% ranging from 65% in March to 71% in October (42). This high relative humidity is of great importance in this type of stone given the open porosity of the tuffs and their common exposure to the outside conditions. These circumstances imply an increase in the thermal transferences of the constructive systems due to the water absorption. In addition, a high risk of condensation should be taken into account for the indoor comfort conditions due to the high relative humidity when the temperature decreases.

As regards the former, Brodsky and Barker (58–59) stated that the thermal conductivity of wet samples doubles the values for the dry samples. Hence, in order to analyze the thermal conductivity dependence on moisture, a simplified model has been considered based on geometric mean (Equation 1). This simple theory was researched by Ashworth who compared it to five other theories and found that it was the most accurate in predicting the performance of stones (59).

Where λ is the thermal conductivity of air (λair), water (λwater) and rock (λrock); n is the porosity and wc is the water content (volume of water in the sample / bulk volume of the sample). It was assumed that the thermal conductivity of still air and still water was 0.026 W/(m.K) and 0.609 W/(m.K), respectively. Porosity values were 36% and 23% for white-dark tuff and brown tuff, respectively (Table 3). The model is based on the existence of two stages: pores filled with air when wc = 0 (dry conditions) which is used to calculate the thermal conductivity of the rock; the second stage with wc = n when the pores were filled with water, to predict the saturated value of the thermal conductivity. Based on this simplification, the thermal conductivity of the saturated rocks was 0.79 W/(m².K) and 0.55 W/(m².K) for the white-dark tuff and the brown tuff, respectively. It means that the thermal conductivity in the wet stage was more than 2 and 3 times higher than that in dry conditions, respectively.

The theoretical results were in agreement with the tests carried out in the wet state. In the latter, the methodology was the same as that of the aforementioned experimental tests with the difference that samples were firstly saturated in water and then wrapped in several layers of polyethylene film. Measurements were taken under steady-state conditions and water content was determined by differences in weight, when thermal conductivity was measured and the dry state followed at 40°C to achieve a constant weight. The thermal conductivities were 0.436 W/(m².K) and 0.475 W/(m².K) of white-dark tuff and brown tuff, respectively, at about 30% of water content. Thus, it implied that the thermal conductivity increased 70–75% with this water. Furthermore, the results confirmed the recommendation of using these stones under protected conditions in order to avoid, not only the acceleration of the stone decay but also the thermal conservation performance of the constructive systems.

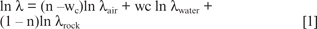

As regards the specific heat capacity, as can be observed in Figure 7a, it varied with the temperature, mainly at low and high temperatures. Considering the colour of the façades and the latitude of the Canary Islands, the surface temperature may be estimated ranging from 10°C in the winter to 80°C in the summer. In this case, the specific heat capacity of samples can be stated at about 1.16 J/(kg.K) for the white-dark tuff and 1.30 J/(kg.K)

for the brown (Figure 7b) with implies a 12% higher accumulation capacity in the latter in comparison to the previous one.

Once again, if the experimental results are compared with the standards, all of the samples showed a higher thermal accumulation capacity than it is supposed. In Spain, the standards stated for porous stones establish a specific heat capacity of 1 J/(kg.K)

which implies that, for instance, the brown tuff showed a 30% higher accumulation capacity than is supposed. It is of great interest since the thermal performance of the constructive system (time lag, decrement factor and thermal inertia, among others)

varied notably depending on the properties assigned.

As regards the thermal emissivity, it was similar to all the samples and to other common building materials. The differences between the samples are probably caused by the mineralogical components. In the case of hot climates, the high emissivity of the surface is of great importance since it avoids an overheating of the surfaces and reduces the thermal stresses of the building materials.

|

Figure 7. a) Specific heat capacity vs temperature. b) Detail of Figure 2a with temperature ranging from 10 to 80°C. Figure 7. a) Specific heat capacity vs temperature. b) Detail of Figure 2a with temperature ranging from 10 to 80°C.

|

|

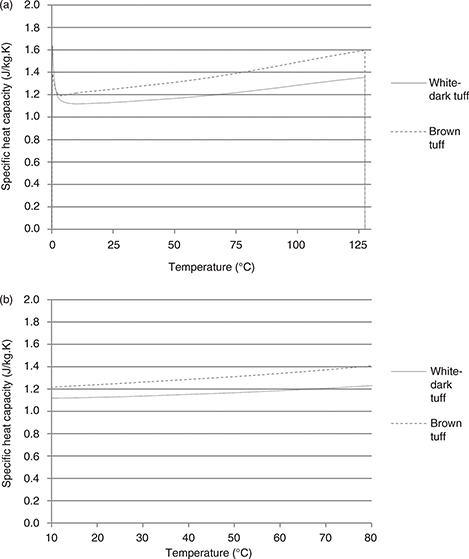

3.4. Simulation in a pseudo-time dependent stateTOP

Finally, the pseudo time-dependent simulation showed that temperatures, time lag and thermal fluxes were reduced with the use of renderings. In Figure 8a, the time lag is about 1 or 2 hours higher in brown tuff with and without renderings when compared to white-dark tuff with the same composition. The differences are greater in mid and high altitude areas compared to coastal ones due to the most variable temperatures. Thermal fluxes (Figure 8b), in the winter, increased slightly 1–6% due to the colour of the façades considering that the renderings were white; in the summer, the thermal fluxes reduced up to 4 times in higher altitudes or 46% in coastal areas, both in cloudy summer days for the brown tuff or 30% to 38% for the white-dark tuff, respectively. Furthermore, taking into account the envisaged effects of climate change, strategies should focus on summer conditions. Then, the preservation of the earth-coloured renderings is recommended which improves the performance not only in the summer but also in winter conditions.

|

Figure 8. a) Thermal fluxes of the constructive systems in the winter. b) Thermal fluxes of the constructive systems in the summer. Figure 8. a) Thermal fluxes of the constructive systems in the winter. b) Thermal fluxes of the constructive systems in the summer.

|

|

This recommendation should be highlighted taking into account the high relative humidity of the Canary Islands. Indeed, the thermal fluxes of the stones increased up to 3 times when the tuffs were saturated compared to the dry conditions in the winter

(Figure 8a). Furthermore, the increase in the thermal transmittance in the constructive systems of the envelope leads to a higher risk of condensation (60) as well as a reduction in thermal comfort. In the summer (Figure 8b), the thermal fluxes also increase up to 2 times, especially on sunny days although the differences are lower than in the winter.

Hence, permeable and specialized renderings (61) considerably improved the energy conservation of the masonry due to the reduction in the thermal fluxes in both winter and summer conditions and its preservation from the humidity. Furthermore, durability increases due to their protection. The capillarity performance of the stones should be taken into account in such a way that the joint between the façade and sidewalk should be constructed correctly to avoid the infiltration of water while allowing the evaporation of the underground water.

3.5. Monitoring in real conditionsTOP

In general, the thermal transmittance values of the ground floor were considerably higher than the that of the first floor. Under state conditions, thermal transmittance of the wall on the ground floor was 0.891 W/m2.K compared to the 0.33 W/m².K of the first floor for the white-dark tuff; while, it was 0.64 W/m².K on the ground floor compared to 0.41 W/m².K on the first floor for the brown tuff. It is important to highlight the lack of precipitation in the last year and its influence on the surface water. In any case, the humidity coming from the ground provoked an increase of 2.7 times the thermal transmittance between both placements for the white-dark tuff and 1.6 times for the brown tuff.

These values confirmed the statement of Baker who insists on the better performance of traditional buildings under real circumstances than under simulation (3, 46). It was of great importance due to the influence of the thermal performance of the constructive systems on the energy demand of the building to achieve conditions of comfort (62).

4. CONCLUSIONSTOP

There is a considerable lack in the characterization of volcanic stones in order to propose the most suitable intervention to be carried out, not only from the mechanical and physical point of view but also from the thermal. In this paper, a complete characterization of two types of volcanic tuffs which are the most widely used on the Island of Gran Canaria in the Canary archipelago was carried out. However, the results can be applied to predicting the performance of other similar tuffs worldwide. Furthermore, recommendations arise as to the implementation of these types of stone in the standards.

As regards the characterization, white-dark tuff showed 16% lower bulk density compared to brown tuff which is related to the 37%, 29% and 17% of higher open porosity, water absorption at 24h and hygroscopicity, respectively; white-dark tuff shows 18%, 44% and 20% of lower compression, flexural strength and hardness, respectively. At the same time, the low flexural/compression ratio implies a high probability of low elasticity modulus and a plastic performance.

As regards the thermal performance, white-dark tuff shows 6% and 11% of lower thermal conductivity and specific heat capacity, respectively, than brown tuff. Furthermore, the effect of the water content on the thermal performance of the stones was analyzed. An increase of 2 or 3 times the thermal conductivity in wet conditions could be predicted. Hence, the worsening of the thermal performance of the masonry together with the high porosity of the stones recommends the use of renderings to avoid the stone decay. Furthermore, the elimination of renderings in the restoration of building also implies an increase in the thermal losses.

Simulation in pseudo-time dependent state show the influence of the water in the masonry in such a way that thermal fluxes increase up to 3 times compared to dry conditions, especially under winter conditions. This finding was in agreement with the real measurements of thermal transmittance in which the difference between the ground and first floor was measured at 2.7 times due to the water content. Furthermore, there is a probability of water condensation increasing in this season and, consequently, a reduction in the indoor comfort.

On the other hand, the use of tuff masonries supported on soils with high levels of ground water can reduce their mechanical strengths and increase the thermal transferences because of their high capillarity behaviour. These circumstances accelerate the decay of the tuff masonry while affecting the living conditions.

ACKNOWLEDGMENTTOP

We appreciate the Building Materials Laboratory at the Escuela Técnica Superior de Arquitectura, Universidad Politécnica de Madrid, as well as the Building Physics Laboratory of Escuela Técnica Superior de Edificación at the same University, for their support and the use of the use of their equipment.

We are grateful to the translation service of the Departamento de Construcción y Tecnología Arquitectónicas for the review of the paper.

REFERENCESTOP

| 1. |

Troitino, M.A. (1998) Turismo y desarrollo sostenible en las ciudades históricas con patrimonio arquitectónico monumental. Estudios Turísticos 137, 211–228. Available at: https://dialnet.unirioja.es/servlet/articulo?codigo=2197398 |

| 2. |

Benito Martín, F.; Timón Tiemblo, M.P. coord. (2014) Plan Nacional de Arquitectura Tradicional, Instituto del Patrimonio Cultural de España, IPCE, Madrid (2014). Available at: http://www.culturaydeporte.gob.es/planes-nacionales/planes-nacionales/arquitectura-tradicional.html |

| 3. |

Baker, P. (2011) U-values and traditional buildings: in situ measurements and their comparisons to calculated values, Historic Scotland, Edinburgh (2011). |

| 4. |

Luxán, M.; Gómez-Muñoz, G.; Barbero-Barrera, M.M.; Román-López, E. (2014) Energy and constructive consequences of a bad practice. Skinned architectures. In M. López, A. Yáñez, S. Gomes da Costa, L. Avellá, coord. Proceedings of the International Conference on Energy Efficiency and Historic Buildings, Fundación de Casas Históricas y Singulares & Fundación Ars Civilis, Madrid. |

| 5. |

Doehne, E.; Price, C.A. (2010) Stone Conservation: an Overview of Current Research, The Getty Conservation Institute, California (2010). Available at: http://www.getty.edu/publications/ |

| 6. |

IGME (2004). Mapa geológico de España. Instituto Geológico y Minero de España, (2004). Available at: http://info.igme.es/cartografia/geologico2000.asp |

| 7. |

Guigou, C. (1990) Influencia de las características petrográficas de los áridos canarios en las propiedades de los hormigones, PhD Thesis, Universidad de Las Palmas de Gran Canaria, Las Palmas de Gran Canaria (1990). |

| 8. |

Concepción, J.L. (1987) Arquitectura y diseño de hogar ideal canario. Arquitectura tradicional, Asociación Cultural de las Islas Canarias (ACIC), La Laguna (1987). |

| 9. |

Steven, L.; Quane, S.L.; Russell, J.K. (2005) Ranking welding intensity in pyroclastic deposits. Bull Volcanol, 67, 129–143. https://doi.org/10.1007/s00445-004-0367-5 |

| 10. |

Giordano, D.; Dingwell, B.; Romano, C. (2000). Viscosity of a Teide phonolite in the welding interval. In: Marti J, Wolff JA (eds), The geology and geophysics of Tenerife, Elsevier, Amsterdam (2000). |

| 11. |

Zárraga, R.; Cervantes, J.; Salazar-Hernández, C.; Wheeler, G. (2010) Effect of the addition of hydroxyl-terminated polydimethylsiloxane to TEOS-based stone consolidants. J Cultural Heritage 11, 138–144. https://doi.org/10.1016/j.culher.2009.07.002 |

| 12. |

Pérez, N.A.; Lima, E.; Bosch, P.; Méndez-Viva, J. (2014) Consolidating materials for the volcanic tuff in western Mexico. J Cultural Heritage 15, 352–358. https://doi.org/10.1016/j.culher.2013.07.010 |

| 13. |

D’Arienzo, L.; Scarfato, P.; Incarnato, L. (2008) New polymeric nanocomposites for improving the protective and consolidating efficiency of tuff stone. J Cultural Heritage 9, 253–260. https://doi.org/10.1016/j.culher.2008.03.002 |

| 14. |

Miliani, C.; Velo-Simpson M.L.; Scherer, G.W. (2007) Particle-modified consolidants: A study on the effect of particles on sol-gel properties and consolidation effectiveness. J Cultural Heritage 8, 1–6. https://doi.org/10.1016/j.culher.2006.10.002 |

| 15. |

Calderoni, B.; Cecere, G.; Cordasco, E.A.; Guerriero, L.; Lenza, P.; Manfredi, G. (2010) Metrological definition and evaluation of some mechanical properties of post-medieval Neapolitan brown tuff masonry. J Cultural Heritage 11, 163–171. https://doi.org/10.1016/j.culher.2009.11.002 |

| 16. |

Topal, T.; Doyuran, V. (1997) Engineering geological properties and durability assessment of the Cappadocian tuff. Eng Geol 47, 175–187. https://doi.org/10.1016/S0013-7952(97)00017-3 |

| 17. |

Erguler, Z.A (2009) Field-based experimental determination of the weathering rates of the Cappadocian tuff. Eng Geol 105, 186–199. https://doi.org/10.1016/j.enggeo.2009.02.003 |

| 18. |

Hee Lee, C.; Seong Lee, M.; Suh, M.; Choi, S.W. (2005) Weathering and deterioration of rock properties of the Dabotap pagoda

(World Cultural Heritage), Republic of Korea. Environ Geol 47, 547–557. https://doi.org/10.1007/s00254-004-1177-y |

| 19. |

Salazar-Hernández, C.; Cervantes, J.; Puy-Alquiza, M.J.; Miranda, R. (2015) Conservation of building materials of historic monuments using a hybrid formulation. J Cultural Heritage 16, 185–191. https://doi.org/10.1016/j.culher.2014.05.004 |

| 20. |

Augenti, N.; Parisi, F. (2011) Constitutive modelling of tuff masonry in direct shear. Constr Build Mat 25, 1612–1620. https://doi.org/10.1016/j.conbuildmat.2010.10.002 |

| 21. |

Felice, B.; Pasquale, V.; Tancredi, N.; Scherillo, S.; Guida, M. (2010) Genetic fingerprint of microorganisms associated with the deterioration of an historical tuff monument in Italy. J. Genet. 89, 253–257. https://doi.org/10.1007/s12041-010-0035-9 |

| 22. |

Martín-Hernández, M.; Alemán-Hernández, R.; López-García, J.S.; Martín-Rodríguez, F.G. (2005) Guía del patrimonio arquitectónico de Gran Canaria, Cabildo de Gran Canaria, Gran Canaria (2005). |

| 23. |

UNESCO. United Nations Educational, Scientific and Cultural Organization. Available at: https://en.unesco.org/ |

| 24. |

González, C. (2006) Las Palmas de Gran Canaria. Sus barrios e instituciones, Anroart Ediciones, Gran Canaria (2006). |

| 25. |

Rodríguez Batlori, A. (1999) La Gesta del Batán: IV Centenario del ataque holandés a Gran Canaria, Ministerio de Defensa, Gran Canaria (1999). |

| 26. |

IGME (2018). Geological map of Spain. Available at: igme.es/cartografiadigital/geologica |

| 27. |

Luxán, M.; Vázquez, M.; Gómez, G.; Román, E.; Barbero-Barrera, M.M. (2009) Actuaciones con criterios de sostenibilidad en la rehabilitación de viviendas en el centro de Madrid, EMVS, Madrid (2009). |

| 28. |

Luxán, M.; Barbero, M.; Gómez, G.; Román, E. (2012). La envolvente como elemento de eficiencia energética. En: Eficiencia Energética y Energías renovables en rehabilitación de edificios. Vigo: Centro Tecnológico de Eficiencia y Sostenibilidad Energética, 172–184. |

| 29. |

International Energy Agency (2015) Energy efficiency. Market Report. Market trends and medium-term prospects, International Energy Agency, France (2015). |

| 30. |

AENOR (2006). EN 1926, Natural stone test methods. Determination of uniaxial compressive strength. |

| 31. |

AENOR (2006). EN 12372, Natural stone test methods. Determination of flexural strength under concentrated load. |

| 32. |

AENOR (2005) EN 14617-4, Agglomerated stone. Test methods. Determination of the abrasion resistance. |

| 33. |

Winkler E.M. (1975) Stone: properties, durability in man’s environment, Ed. Springer-Verlag Wien GmbH (1975). |

| 34. |

Veiga, M.R. (2009) Characteristics of repair mortars for historic buildings concerning quantified hygric requirements. In: Groot C, ed. Proceedings 078: Repair Mortars for Historic Masonry TC RMH, RILEM, France, 305–315. |

| 35. |

AENOR (2008) EN 13755, Natural stone test methods. Determination of water absorption at atmospheric pressure. |

| 36. |

AENOR (1999) EN 1925, Natural stone test methods. Determination of water absorption coefficient by capillarity. |

| 37. |

AENOR (2006) EN 1936, Natural stone test methods. Determination of real density and apparent density, and of total and open porosity. |

| 38. |

Navacerrada, M.A.; Fernández, P.; Díaz, C.; Pedrero, A. (2013) Thermal and acoustic properties of aluminium foams manufactured by the infiltration process. Applied Acoustics 74, 496–501. https://doi.org/10.1016/j.apacoust.2012.10.006 |

| 39. |

PHYWE. P2360300 series of publications. Laboratory Experiments, Physics. Göttingen: PHYWE SYSTEME GMBH & Co. KG |

| 40. |

ASTM (2004) C1371-04a, Standard Test Method for Determination of Emittance of Materials Near Room Temperature Using Portable Emissometers. |

| 41. |

Martín-Monroy, M. (1996) Comportamiento térmico de cerramientos soleados: un modelo de simulación por diferencias finitas, PhD Thesis, Universidad de Las Palmas de Gran Canaria, Las Palmas de Gran Canaria (1996). |

| 42. |

AEMET (2018). Climate database. Available at www.weatherbase.com. |

| 43. |

CTE (2015). Documento básico HE Ahorro de Energía, HE1: Limitación de demanda energética, Madrid, Ministerio de Industria, Turismo y Comercio, 2015. Available at: http://www.codigotecnico.org |

| 44. |

Peng, C.; Wu, Z. (2008) In situ measuring and evaluating the thermal resistance of building construction. Energy Build. 40 (11), 2076–2082. https://doi.org/10.1016/j.enbuild.2008.05.012 |

| 45. |

Adhikari, R.S.; Lucchi, E.; Pracchi, V (2012) Experimental measurements on thermal transmittance of the opaque vertical walls in the historical buildings. In: J. Reiser, C. Jiménez, S. Biondi Antúnez de Mayolo (Eds.), Proceedings of PLEA2012. 28th Conference, Opportunities, Limits & Needs Towards an Environmentally Responsible Architecture, Lima, 7–9 November 2012, 1248–1256. |

| 46. |

Rasooli, A.; Itard, L., Infante Ferreira, C. (2016) A response factor-based method for the rapid in-situ determination wall’s thermal resistance in existing buildings. Energy and Buildings 119, 51–61. https://doi.org/10.1016/j.enbuild.2016.03.009 |

| 47. |

Lucchi, E. (2017) Thermal transmittance of historical stone masonries: A comparison among standard, calculated and measured data. Energy and Buildings 151, 393–405. https://doi.org/10.1016/j.enbuild.2017.07.002 |

| 48. |

Prota, A.; Marcari, G.; Fabbrocino, G.; Manfredi, G.; Aldea, C. (2006) Experimental in-plane behavior of tuff mansonry strengthened with cementitious matrix-grid composites. J Composites for Construction 10, 223–233. https://doi.org/10.1061/(ASCE)1090-0268(2006)10:3(223) |

| 49. |

Asprone, D.; Cadoni, E.; Prota, A.; Manfredi, G. (2009) Dynamic behavior of a Mediterranean natural stone under tensile loading. Int. J Rock Mech & Min Sci 46, 514–520. https://doi.org/10.1016/j.ijrmms.2008.09.010 |

| 50. |

Vielba-Cuerpo, C.; Hernández-Olivares, F. (2001) Tests to characterize the behaviour of natural Stone in contact with water. Mater Constr 52, 43–54. https://doi.org/10.3989/mc.2002.v52.i267.325 |

| 51. |

Jackson, M.D.; Marra, F.; Hay, R.L.; Cawood, C.; Winkler, E.M. (2005) The judicious selection and preservation of tuff and travertine building stone in ancient Rome, Archaeometry 47, 485–510. https://doi.org/10.1111/j.1475-4754.2005.00215.x |

| 52. |

D’Agostino, D. (2013) Moisture dynamics in an historical masonry structure: The Cathedral of Lecce (South Italy). Building and Environment 63, 122–133. https://doi.org/10.1016/j.buildenv.2013.02.008 |

| 53. |

Benavente, D.; García del Cura, M.A.; Fort, R.; Ordóñez, S. (2004) Durability estimation of porous Building stones from structure and strength. Engineering Geology 74, 113–127. https://doi.org/10.1016/j.enggeo.2004.03.005 |

| 54. |

Ulusoy, M. (2007) Different igneous masonry blocks and salt crystal weathering rates in the architecture of historical city of Konya, Building and Environment 42, 3014–3024. https://doi.org/10.1016/j.buildenv.2005.01.020 |

| 55. |

Wanja Wedekind, Rubén López-Doncel, Reiner Dohrmann, Mathias Kocher, Siegfried Siegesmund (2013), Weathering of volcanic tuff rocks caused by moisture expansion, Environmental Earth Sciences 69, 1203–1224. https://doi.org/10.1007/s12665-012-2158-1 |

| 56. |

Cioffi, R.; Marino, O.; Mascolo, G. (1991) The physical action of water on the decay of building grey-tuff stone. Mat Eng 2, 263–275. |

| 57. |

LIDER Sofware (2015) Documento básico HE Ahorro de Energía. HE1: Limitación de demanda energética, Madrid, Ministerio de Industria, Turismo y Comercio. |

| 58. |

Brodsky, N.S.; Barker, G.T. (1999) Thermal conductivity as a function of saturation for welded and nonwelded tuff. In: Proceedings of the 37th US Rock Mechanics Symposium, Vail Colorado, June 6–9. Balkema, Rotterdam, 699–705. |

| 59. |

Ahsworth, E. (1992) The variation of the thermal conductivity of tuff with moisture. Experimental results and proposed model. In Tillerson & Wawersik, eds, Rock Mechanics, Balkema, Rotterdam, 859–868. |

| 60. |

Hens H.S.L.C (2006) The vapor diffusion resistance and air permeance of masonry and roofing systems. Building and Environment

41, 745–755. https://doi.org/10.1016/j.buildenv.2005.03.004 |

| 61. |

Barbero-Barrera, M.M.; Maldonado-Ramos, L.; Van Balen, K.; García-Santos, A.; Neila González, F.J. (2014) Lime renders layers: an overview of their properties. J. Cult Her 3, 326–330. https://doi.org/10.1016/j.culher.2013.07.004 |

| 62. |

Cesaratto, P.G.; De Carli, M. (2013) A measuring campaign of thermal conductance in situ and possible impacts on net energy demand in buildings. Energy and Buildings 59, 29–36. https://doi.org/10.1016/j.enbuild.2012.08.036 |

Figure 1. Maps by the engineer Leonardo Torriani. In 1590, on the left the map of Vegueta-Triana (Las Palmas de Gran Canaria, Gran Canaria) and, on the right, San Francisco and San Juan in the 16th Century (Telde, Gran Canaria). On both maps the quarries of tuff near the historical sites are shown: Batán-Barranco Seco (B) and Caserones (C). On the Map of Caserones the pre-hispanical site of Tara in Telde can be also seen (A).